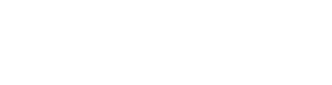

Using the Balanset-1A Instrument

Preparing the Necessary Tools

- vibration sensors, optical speed sensor, magnetic base, software package, and included accessories.

- Connect the device to your PC using the USB interface and confirm the software installation.

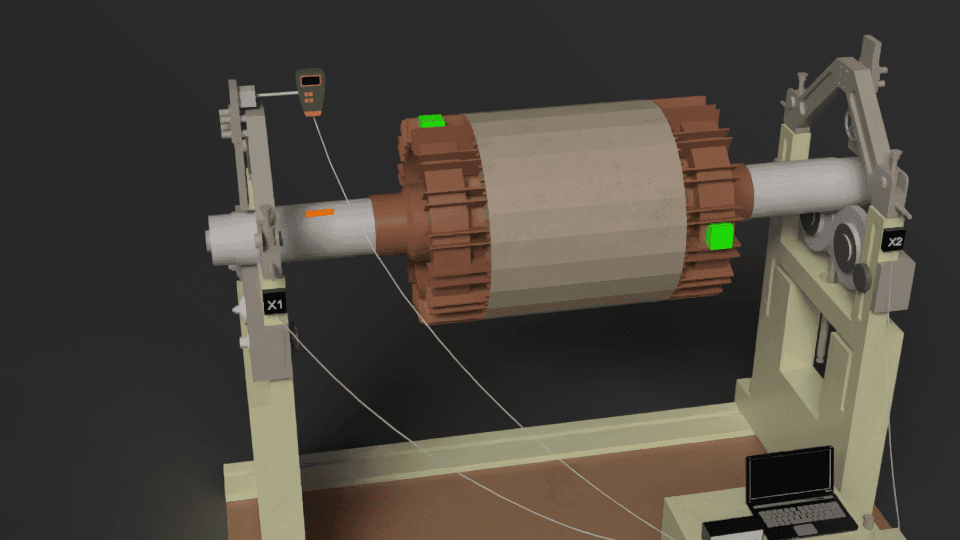

Mounting the Sensors

- Attach the vibration sensors firmly to the machine casing in areas with the highest vibration amplitude, usually close to the bearing supports.

- Direct the laser speed sensor towards the rotor and affix reflective tape to the rotor surface to facilitate phase angle measurement.

Software Startup

- Initiate the Balanset program on your computer.

- Choose the correct balancing method (single or two-plane) according to the rotor configuration and the balancing task.

Taking Baseline Vibration Readings

- Run the rotor up to its operating speed.

- The program will record the vibration amplitude, rpm, and phase, providing a baseline measurement of the existing imbalance.

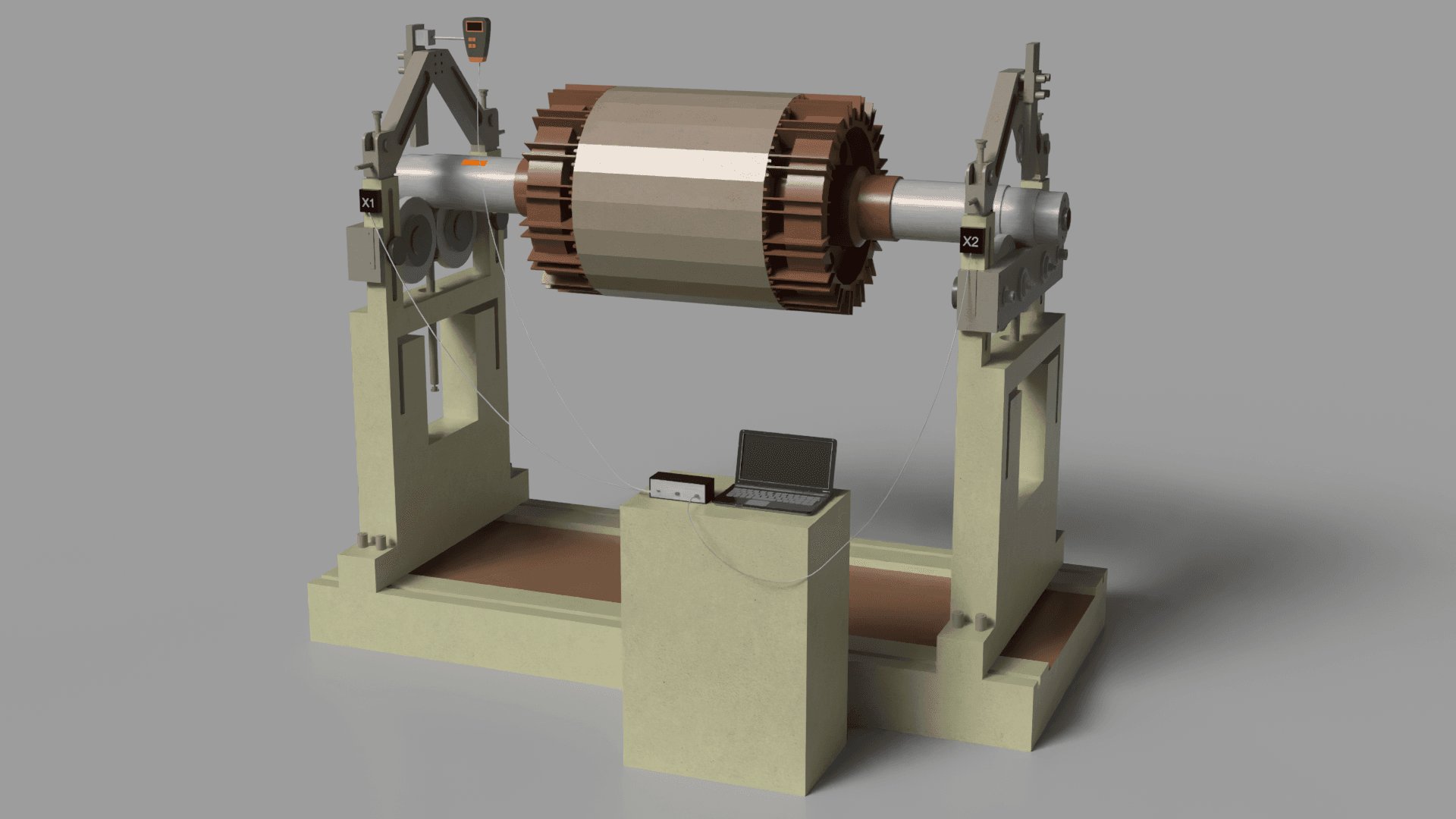

Trial Weight Installation

- Bring the rotor to a standstill and affix a trial weight at a predetermined point on the rotor, specifying its mass in the software (typically in grams).

- Resume rotor operation, and the program will capture the resulting changes in vibration amplitude and phase.

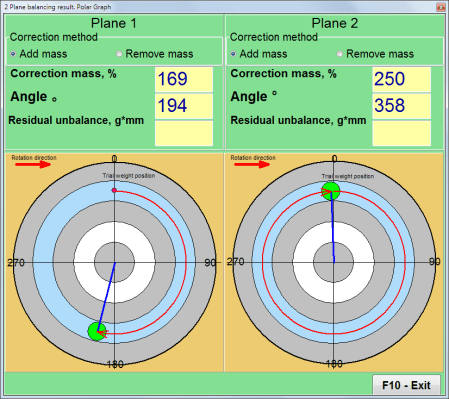

Calculating the Correction Weight

- Based on the measured data, the software automatically calculates the correction weight parameters: mass and installation angle.

- These parameters are displayed on the screen as numerical data and graphs.

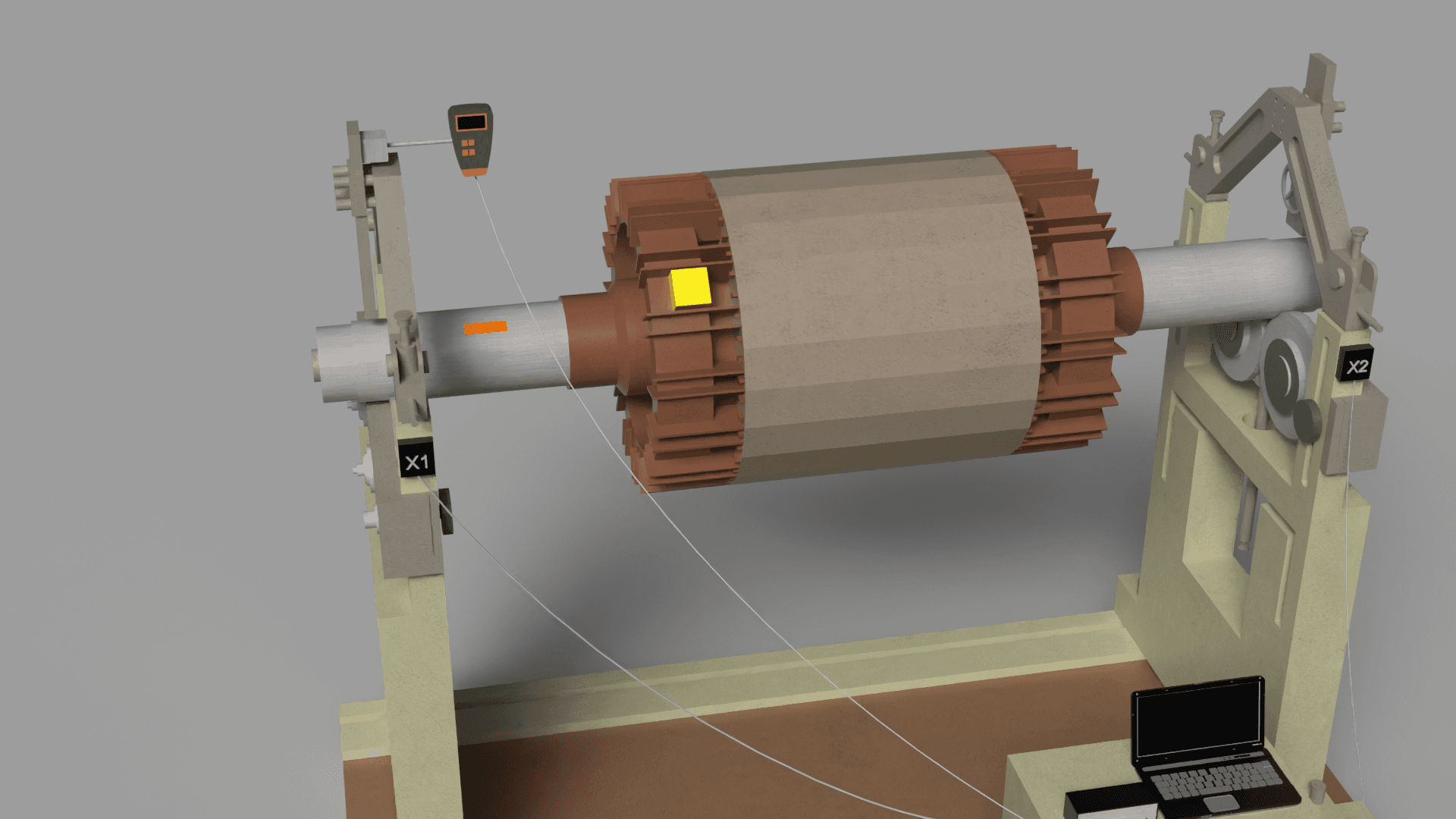

Installing the Correction Weight

- Attach the computed compensating weight to the rotor as indicated by the software’s output.

- Periodic checks can be performed to ensure the balancing procedure is effectively reducing the vibration.

Verification and Balancing Completion

- With the compensating weight attached, operate the rotor and assess the level of any residual vibration.

- The balancing procedure is finished if the remaining vibration is within the permissible limits specified in ISO 1940.

- If the vibration is still outside acceptable limits, reiterate the process and fine-tune the compensating weight.

Report Generation

- The program stores the balancing data, allowing you to generate and print a comprehensive report including vibration measurements, corrective weight details, and its angular placement.

Post-Balancing Checklist

- Ensure all applied weights and attached sensors are firmly fixed in their designated positions.

- Ensure the rotor rotates smoothly and without excessive noise.

- In cases where the rotor is integrated into a more complex system, ensure the correct operation and interaction of all related components.

By implementing this method, you can effectively eliminate imbalance, reduce vibration levels, and increase the lifespan of the machinery.

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL

Our website about Vibration control

Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal

Facebook: https://www.facebook.com/marketplace/item/350151228150722

https://felixkynb36925.thekatyblog.com/25663394/hassle-free-balancing-introducing-the-new-balanset-device